Xiamen Paia Import & Export Co., Ltd +86-13799795006 [email protected]

Project Challenges: The flooring required a combination of water jet cuting and mosaic craftsmanship, which posed several unique challenges: 1. Thickness Limitation: Cutting 1cm marble is extremely difficult and prone to breakage or edge chipping. 2....

Project Challenges:

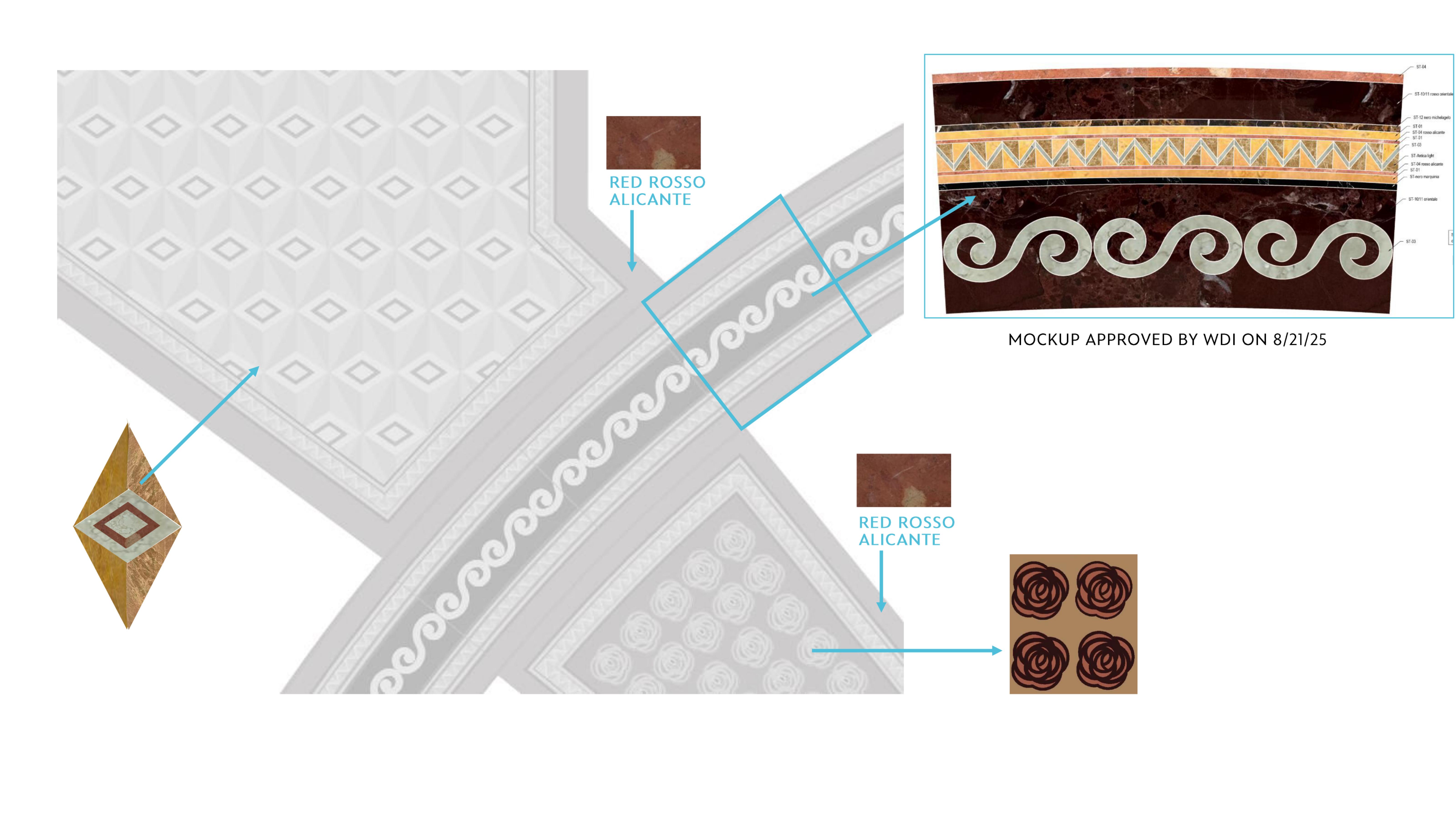

The flooring required a combination of water jet cuting and mosaic craftsmanship, which posed several unique challenges:

1. Thickness Limitation:

Cutting 1cm marble is extremely difficult and prone to breakage or edge chipping.

2. Craft Integration:

The project required the precision of waterjet patterns while maintaining the meticulous detail of mosaic assembly.

3. Color Coordination:

The client had exceptionally high requirements for the balance and transition of different colors,demanding.

4. Structural Complexity:

The laminated panels had to ensure fatness and durability, preventng misalignment or uneven gaps during installation.

Our Solutions:

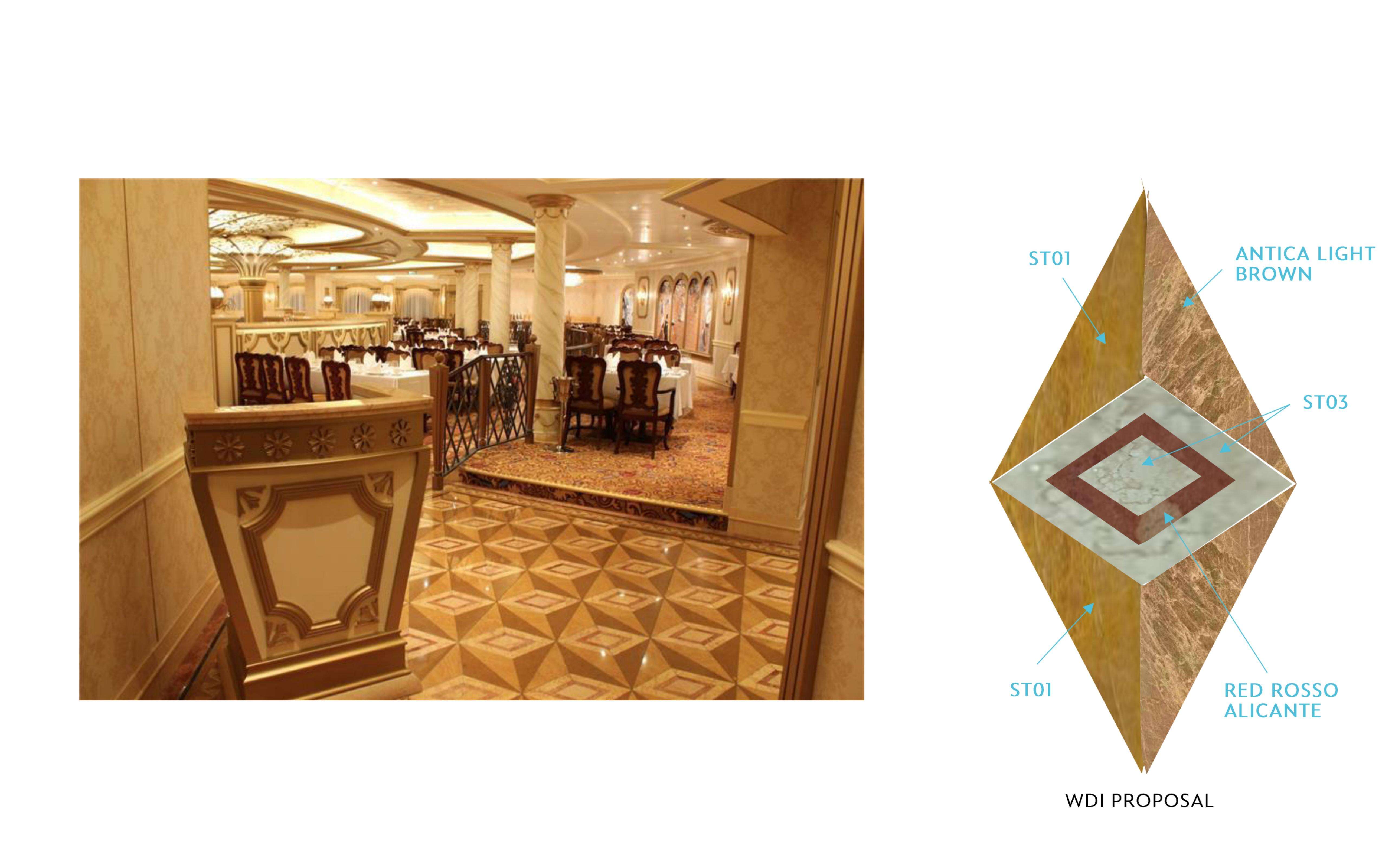

This project involved a custom-designed flooring for a luxury yacht, with a structure of 1 cm marble laminated onto 1cm backing material.

1. Preserving Original Slab Surface:

Before cutting, the original slab surface was retained to avoid surface defects caused by secondary processing.

2. Reinforced Lamination Process:

Traditional and reliable reinforcement methods were applied to ensure the 1cm+1cm laminated panels stayed aligned during assembly.

3. Exclusive Waterjet Cutting:

All cutting was executed entirely by waterjet to guarantee precision and eliminate edge chipping or corner damage.

4. Strict Color Control:

Each marble piece was carefully selected and positioned to achieve perfect harmony in color matching and high-end visual effect.

|

|

|

|

|

|